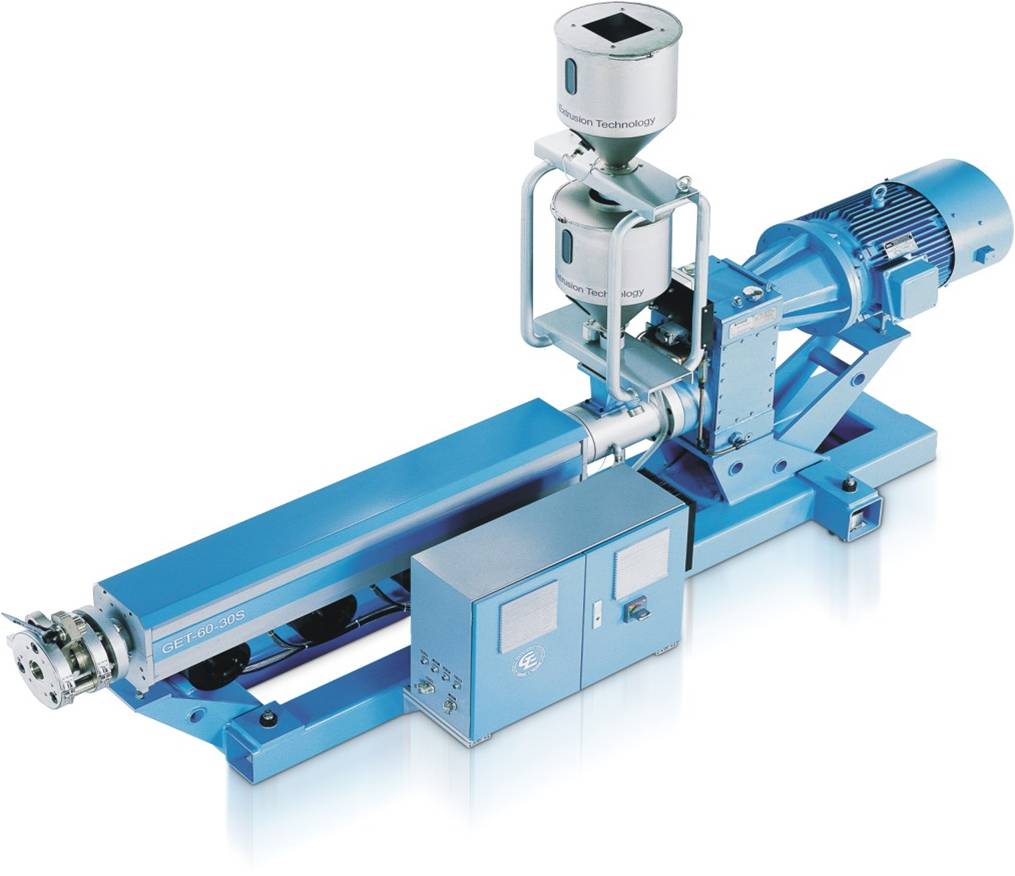

The newly developed 5 layer film blowing co-extruder GET-ARSENAL is capable to manufacture film by the latest Exxon Mobil technologhy.

has the following main features:

- 5-layer binary cylindrical (telescopic) extrusion 350 mm die with IBC

- Two nozzle adjustable cooling ring with APC

- Total dozing Syncro (Italy) control, loss-n-weight, specific and total output for each layer

- HMI PLC 360 degrees integrated control system with CE components, touch screens and accelerated fusion logic algorithms

- Adaptive APC with immediate corrective actions resulting with ±1 per cent film gauge variation (absolute value less then 1 micron, know how), both MD and TD

- Rotating nip rolls, carbon rolls on motor driven collapsing frame and cage

- Helical grooved feeding Helibar extrusion technology

- Maileffer spiral barrier screw with Gregory-Barr mixing

- Ground gear two stage silent reducers

- German web positioniing system

- Gap-contact central auto hi-speed winder 2000 mm with shaft extractor and full cycle re-load

- 1 operator ready

- Visits to operational lines any time, online film sample collection and inspection for qualilty

- output up to 400 kg per h

- Price US$ 700 thousand for fully loaded line

- Manufacturing period 3 months

- Warranty 18 months

EXON MOBIL and Windmöller und Hölscher specialists consider

5 layer co-extrusion to replace 3-layer technologies within nearest 10 years

Details, formulations and ideas are available here:

EXXON MOBIL 5 LAYER POLYOLEFINE FILM KNOW HOW (pdf file 1.8M)

7 ADVANTAGES AND KEY FEATURES OF GET-ARSENAL FILM BLOWING EXTRUDERS

1.Best plasticization and homogenization of polymer due Helibar™ technology, helical grooved feeding, 1:34 Mailifer screw with Gregory-Barr mixer, 25 per cent power saving due to use of Gruenschloss thermo-balanced extruders

2.Best gauge tolerance and changeover time due to high pressure spiral die, individually retailed to your needs

2.Best gauge tolerance and changeover time due to high pressure spiral die, individually retailed to your needs

3.Automated profile control with no-delay sensors, fast fusion logic algorithms, instant heating actuators resulting to extra tolerances, roll quality and resin saving

4.Fast PLC controls with adwanced algorithms and comfortable HMI

5.Use of step motors, rotating nips, carbon rolls, proven components, high grade materials and precision CNC machining

6.Complete service and technological support available trough international engineering network

7.Fully automated gap-contact winding system

Finally, you get more machine for money

Other types of product:

- Extrusion coating lines for paper, film and Alufoil

- Double Bubble extruders for pof film

- Triple Bubble extruders for shrink barrier film

- Cast lines

- Twist and pof-twist lines

- Calander lines for PU, PE, TPE, PP and more.

|